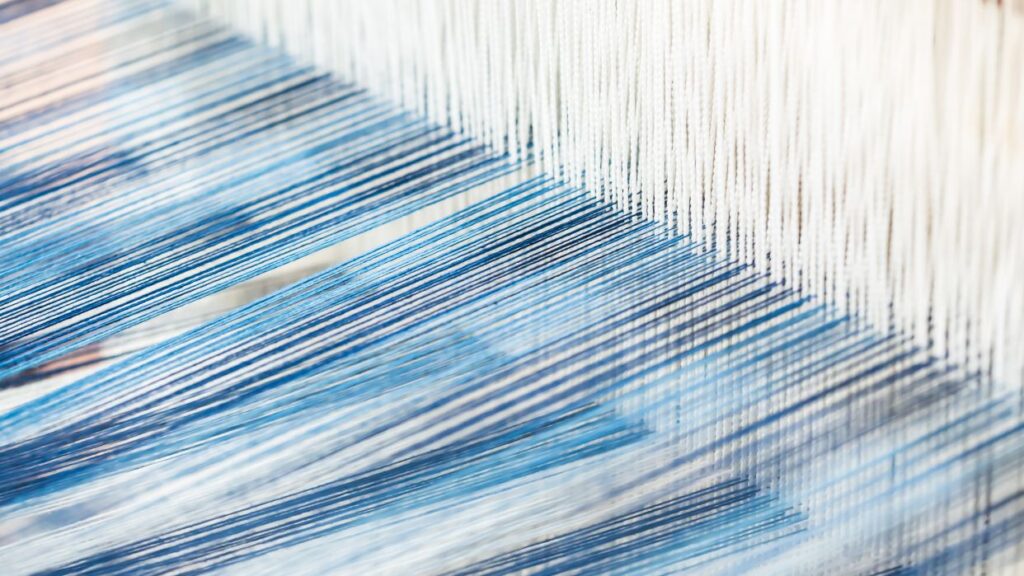

Weaving

Weaving 10,000 Meters Per Day

We have experience of over 70 years in fabric manufacturing. Our fabric manufacturing capabilities include fabrics like Poly-Cotton blends in Yarn Dyed + Plain Dyed, 100% Cotton Yarn Dyed + Plain Dyed, 100% Bamboo, 100% Recycled Polyesters, 100% Linen, and many more. These facilities are further designed to optimize material flow distance to produce 10,000 meters of fabric per day. Our textile facilities are certified with the highest industry standards. We are capable of supplying OEKO-Tex, Recycled Cotton, and various other fabrics.

Our Cutting Edge Machinery

30 LOOMS

Somet Super Excel

16 LOOMS

Sulzer PUK R1

16 LOOMS

Sulzer PUK R2

16 LOOMS

Sulzer TW11 KR1

16 LOOMS

Sulzer TW11 KP